The Turner Valley Gas Plant was the first refinery in Western Canada, marking a significant milestone in Alberta’s and Canada’s natural resource history. Over its years of operation, it processed not only oil but also natural gas, removed hydrogen sulfide, and produced gasoline, isobutane, propane, elemental sulfur, and more. Its facilities and equipment showcase the evolution of natural resource processing and technological advancements in the oil and gas sector. More on calgary-name.com.

The Discovery of Oil and Gas in Turner Valley

In the latter half of the 19th century, oil and gas deposits were discovered in southern Ontario and Pennsylvania. These resources became critical energy sources for the industrial economies of Canada and the United States.

Starting in 1871, the Geological Survey of Canada and the Dominion Land Survey sent expeditions to map and explore the land, preparing it for settlement and identifying valuable resources. Oil and gas, often buried deep underground without surface indicators, required mapping to pinpoint their presence and select drilling sites.

It was discovered that the region now known as southern Alberta was rich in oil and gas. By the 1910s, natural gas wells in Medicine Hat, Bow Island, and areas near Calgary were producing enough to meet local heating and industrial needs.

On May 14, 1914, the Dingman No. 1 well struck oil and gas in southern Alberta, where the town of Turner Valley would later emerge. This marked the first major oil and gas discovery in Alberta. The importance and value of this find were immediately recognized by both provincial and federal governments. Oil was seen as the fuel of the future, capable of powering boilers, compressors, various modes of transportation, and agricultural machinery.

The Plant’s Early Operations

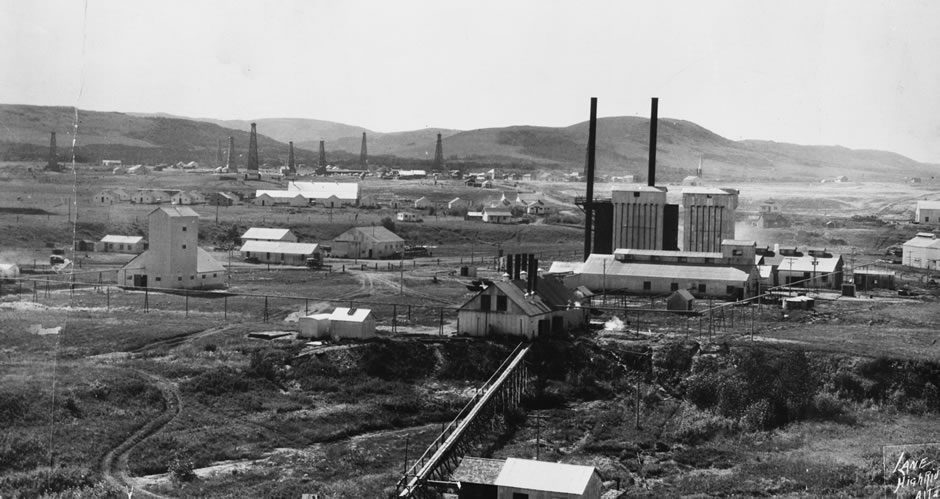

The Turner Valley Gas Plant began operations during the first development phase under Calgary Petroleum Products. This company established the initial infrastructure between 1914 and 1920.

The Dingman No. 1 well was already in operation, and starting in 1914, the plant focused on processing oil by removing sulfur and refining residues to produce a specific type of gasoline. Initially, the gasoline produced was used to fuel the plant’s steam boilers. Over the years, the plant underwent numerous name changes.

Turner Valley quickly became a hub of activity and a settlement site for workers and their families. The oil and gas industry significantly influenced the growth and decline of the community, shaping daily life in Turner Valley.

Ownership Changes and Shifting Focus

A fire destroyed the plant in 1920. By 1921, it was acquired by Imperial Oil, which undertook its restoration. While Calgary Petroleum Products had focused on oil extraction, Imperial Oil shifted the emphasis to natural gas. A subsidiary of Imperial Oil, the Royalite Oil Company, Limited (Royalite), managed drilling in the Turner Valley region and operated the plant.

Royalite added a new absorption facility and a compressor system. The absorption facility extracted gasoline from wet gas, while the compressor system pressurized the gas for transmission.

The company also reached an agreement with Canadian Western Natural Gas to use its pipelines for transporting natural gas from Turner Valley to Calgary. Royalite built a connecting pipeline from the plant to Okotoks, linking it to the Bow Island pipeline. By 1923, the compressor capacity had doubled.

On February 23, 1930, Turner Valley was officially registered as a village. The town’s name originates from Robert and John Turner, who settled there in 1886. Turner Valley became a town on September 1, 1977, and merged with Black Diamond on January 1, 2023, to form Diamond Valley.

The Era of Propane and Sulfur

The post-war period saw new ownership and a focus on different products. In 1948, Montreal’s Bronfman family acquired a controlling stake and worked alongside Royalite. The family introduced technologies for producing propane and sulfur.

American engineer James Barber pioneered propane production in Turner Valley. Recognizing that the gas flared at the plant contained ethane and propane, Barber founded Western Propane in 1948 to produce and sell propane. He built a plant half a mile from the main Turner Valley facility.

Western Propane produced 99% pure propane, but market demand fell short of Barber’s expectations. In 1952, he sold Western Propane to Royalite, which dismantled the equipment and relocated it to its facility.

While propane brought significant profits due to its industrial, household, and recreational uses, sulfur production held even greater potential for Royalite. Sulfur was widely used in sulfuric acid, fertilizers, pulp production, batteries, detergents, cosmetics, and medicines. The plant also produced isobutane.

In the early 1950s, Royalite contracted engineering firm Foster Wheeling Ltd. to install equipment for extracting sulfur from the hydrogen sulfide found in Turner Valley’s natural gas. In July 1952, the facility launched “Operation Brimstone,” as the sulfur extraction process was called. The product was transported to Okotoks for distribution across Canada.

Gradual Decline

Over the next forty years, no major developments occurred at the plant aside from equipment upgrades. In 1972, a new fractionating unit was added for gasoline production. However, the discovery of vast oil reserves in Leduc in 1947 and Redwater in 1948 shifted the focus of the industry to northern Alberta. The gradual decline in Turner Valley production was also influenced by decreasing gas pressure caused by wasteful flaring.

In 1962, British American Oil (later Gulf Oil) acquired the plant, followed by Western Decalta in 1977. In 1985, Western Decalta decommissioned the facility.

Legacy

The Turner Valley Gas Plant’s history is one of adaptation and innovation in the face of economic and technical challenges. From its founding to the 1950s, it was a leader in Canada’s gas processing technologies. The preserved structures at the site now serve as a historical landmark, commemorating Alberta’s oil and gas industry development.